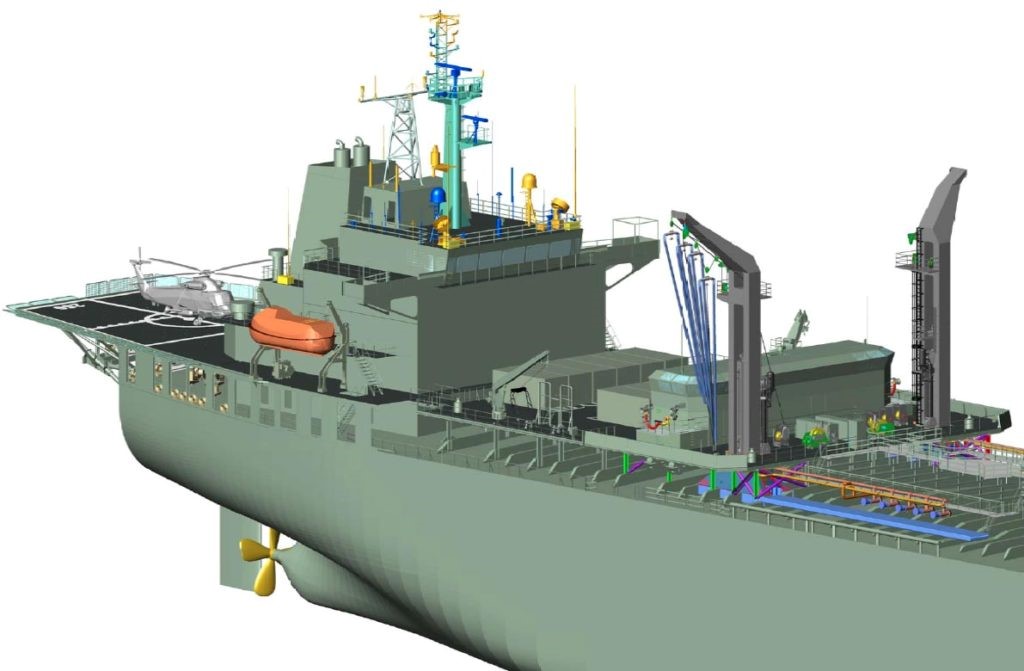

AMT commenced at the very start of this Program in providing advisory support to the CoA during the initial acquisition of the base ship, with expert advice in the acquisition of a vessel that would be most appropriate and of lowest risk for subsequent conversion. AMT was subsequently contracted by the Prime Contractor, Tenix, to perform and provide the principle, detail and production design of the conversion, which includes a full Replenishment at Sea facility, an aviation capability and significant platform system, accommodation and outfit changes to meet the operational, performance and availability requirements specified in the Navy’s Mission System Specification and what were then very new Lloyds Register Naval Ship Rules.

AMT’s design for the modification involved updates to the ship platform systems including tank usage, electrical system, sewage treatment system and other ship distributed support systems, and the addition of a new section of deck to provide storage space and support facilities including power for up to 12 ISO Containers and new RHIBs. The RHIBs and davits from HMAS WESTRALIA

as well as larger enclosed SOLAS lifeboats were installed.

Being an acquisition of a second-hand ship from a commercial owner meant very little design documentation was acquired in the sale/purchase of the base ship. This created many design challenges where AMT needed to reverse-engineer the design intent in the design modification of many onboard systems. A significant example was in the need for a Ship Global Strength Structural

Design Assessment (SDA) to meet Lloyds Requirements, where AMT had only a small set of structural drawings on hand, to then recreate the full structural design definition, to build the FEA Model for analysis for LR Approval. And all within a period of only a few months!!

Additionally, a new flight deck was designed and installed in the form of a cantilevered structure (the first such structure designed to Lloyd’s Naval Rules) and the accommodation was significantly modified to accommodate the larger Navy crew numbers. A Rexroth Hydradyne RAS System was installed to provide the vessel with underway liquids replenishment (supply and receive) capability commensurate with the role of a fleet tanker.

AMT’s design included the integration of significant communications and electronic equipment to support the naval operational capabilities, meeting naval physical security and Electromagnetic security requirements.

This significant and complex project was completed ahead of schedule where the Prime Contractor was awarded a financial bonus, the CoA Project Office achieved an Award in Project Management and AMT received a certificate from Engineers Australia for Engineering Excellence.

These are the types of Programs for which AMT’s whole of naval ship design team capabilities are so well suited.

Share Article